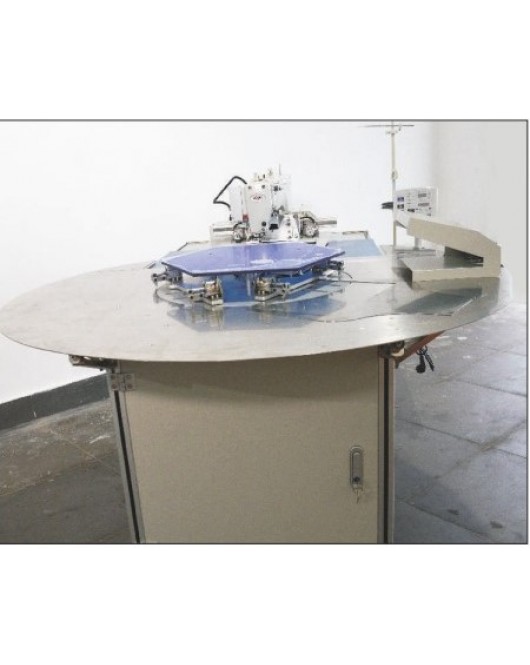

SEPA PATTERN SEWING LOADER

- Product Code: PRA1001554

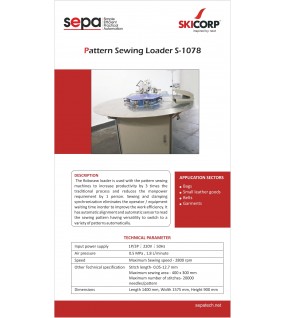

The Robosew loader is used with the pattern sewing machines to increase productivity by 3 times the traditional process and reduces the manpower requirement by 1 person. Sewing and clamping synchronization eliminates the operator/equipment waiting time in order to improve the efficiency. It has automatic alignment and automatic sensor to read the sewing pattern having versatility to switch to a variety of patterns automatically.

SEPA PATTERN SEWING LOADER

| Air Specifications | |

|---|---|

| air pressure L/min | 1.8 |

| APPLICATIONS | |

| BELT | NO |

| SHOES | NO |

| WALLETS | Yes |

| HANDBAGS | Yes |

| ELECTRICAL SPECIFICATIONS | |

| electricity Hertz | 50 |

| Input Power supply | 1P/3P;220V; |

| Functional Specifcations | |

| Footdrive press mode | Pneumatic |

| Height of pressure foot Max mm | 30 |

| Intermittent pressure on tip / mm | 10-Feb |

| Intermittent pressure rise | 22 |

| Max nr of stitches needle /pattern | 20000 |

| Max Sewing speed rpm | 2800 |

| Range of Gluing | NA |

| sewing area mm | 400 x 300 |

| stitch length mm | 0.05-12.7 |

| GROUP PRODUCTIONS | |

| GROUP PRODUCTIONS | YES |

| LINE PRODUCTIONS | |

| LINE PRODUCTIONS | Yes |

- Brand: SEPA

- Viewed: 8448

| Air Specifications | |

|---|---|

| air pressure L/min | 1.8 |

| APPLICATIONS | |

| BELT | NO |

| SHOES | NO |

| WALLETS | Yes |

| HANDBAGS | Yes |

| ELECTRICAL SPECIFICATIONS | |

| electricity Hertz | 50 |

| Input Power supply | 1P/3P;220V; |

| Functional Specifcations | |

| Footdrive press mode | Pneumatic |

| Height of pressure foot Max mm | 30 |

| Intermittent pressure on tip / mm | 10-Feb |

| Intermittent pressure rise | 22 |

| Max nr of stitches needle /pattern | 20000 |

| Max Sewing speed rpm | 2800 |

| Range of Gluing | NA |

| sewing area mm | 400 x 300 |

| stitch length mm | 0.05-12.7 |

| GROUP PRODUCTIONS | |

| GROUP PRODUCTIONS | YES |

| LINE PRODUCTIONS | |

| LINE PRODUCTIONS | Yes |

The Robosew loader is used with the pattern sewing machines to increase productivity by 3 times the traditional process and reduces the manpower requirement by 1 person. Sewing and clamping synchronization eliminates the operator/equipment waiting time in order to improve the efficiency. It has automatic alignment and automatic sensor to read the sewing pattern having versatility to switch to a variety of patterns automatically.

SEPA PATTERN SEWING LOADER