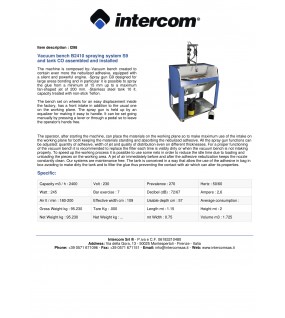

MANUAL SPRAY SYSTEMS I988 BENCH B9+S8+TANK

- Product Code: PRE1000239

The machine is composed by: -Vacuum bench created to absorb even more the nebulized adhesive, equipped with two silent and powerful engines. -Spray gun G6 is designed for both precise and large areas bonding. In particular, it is possible to spray the glue from a minimum of 3 mm up to a maximum of 50 mm. -Stainless steel tank 10 lt. capacity, treated with non-stick Teflon. Vacuum bench with wheels for easy displacement inside the factory. The bench can be connected to other modules so as to increase the working surface while meeting the requirements of clients producing big-sized items. The spray gun is held up by an equalizer for making it easy to handle. It can be operated manually by pressing a lever or through a pedal to leave the operator's hands-free. The operator, after starting the machine, can place the materials on the working plane so to make maximum use of the intake on the working plane for both keeping the materials standing and absorbing the nebulized adhesive. All the spray gun functions can be adjusted: quantity of adhesive, width of jet and quality of distribution even on different thicknesses. For the proper functioning of the vacuum bench it is recommended to replace the filter each time is visibly dirty or when the vacuum bench is not intaking properly. To speed up the working process it is possible to use some nets in order to reduce the idle time due to loading and unloading the pieces on the working area. A jet of air immediately before and after the adhesive nebulization keeps the nozzle constantly clean. Our systems are maintenance free. The tank is conceived in a way that allow the use of the adhesive in bag in box avoiding to make dirty the tank and to filter the glue thus preventing the contact with air which can alter its properties.

| MANUAL SPRAY SYSTEMS I598 BENCH B1510+S9+TANK |

| Air Specifications | |

|---|---|

| air pressure L/min | 30 |

| APPLICATIONS | |

| BELT | Yes |

| SHOES | Yes |

| WALLETS | Yes |

| HANDBAGS | Yes |

| ELECTRICAL SPECIFICATIONS | |

| Ampere | 2.6 |

| Decibel (dB) | 72/67 |

| electricity Hertz | 50/60 |

| Electricity Prevalence | 270 |

| Input Power supply | 230V |

| Power consumption | 245 X 2 |

| Volume M3 | 2.358 |

| Functional Specifcations | |

| Effective Width mm | 1740 |

| Usable depth mm | 700 |

| GROUP PRODUCTIONS | |

| GROUP PRODUCTIONS | Yes |

| LINE PRODUCTIONS | |

| LINE PRODUCTIONS | Yes |

| Physical Specifications | |

| Net Weight(kg) | 127 |

| Length(mm) | 700 |

| Gross Weight(kg) | 127 |

| Width(mm) | 1760 |

| Height(mm) | 1700 |

| Capacity M2 | 2400 X 2 |

- Brand: INTERCOM

- Viewed: 3472

| Air Specifications | |

|---|---|

| air pressure L/min | 30 |

| APPLICATIONS | |

| BELT | Yes |

| SHOES | Yes |

| WALLETS | Yes |

| HANDBAGS | Yes |

| ELECTRICAL SPECIFICATIONS | |

| Ampere | 2.6 |

| Decibel (dB) | 72/67 |

| electricity Hertz | 50/60 |

| Electricity Prevalence | 270 |

| Input Power supply | 230V |

| Power consumption | 245 X 2 |

| Volume M3 | 2.358 |

| Functional Specifcations | |

| Effective Width mm | 1740 |

| Usable depth mm | 700 |

| GROUP PRODUCTIONS | |

| GROUP PRODUCTIONS | Yes |

| LINE PRODUCTIONS | |

| LINE PRODUCTIONS | Yes |

| Physical Specifications | |

| Net Weight(kg) | 127 |

| Length(mm) | 700 |

| Gross Weight(kg) | 127 |

| Width(mm) | 1760 |

| Height(mm) | 1700 |

| Capacity M2 | 2400 X 2 |

The machine is composed by: -Vacuum bench created to absorb even more the nebulized adhesive, equipped with two silent and powerful engines. -Spray gun G6 is designed for both precise and large areas bonding. In particular, it is possible to spray the glue from a minimum of 3 mm up to a maximum of 50 mm. -Stainless steel tank 10 lt. capacity, treated with non-stick Teflon. Vacuum bench with wheels for easy displacement inside the factory. The bench can be connected to other modules so as to increase the working surface while meeting the requirements of clients producing big-sized items. The spray gun is held up by an equalizer for making it easy to handle. It can be operated manually by pressing a lever or through a pedal to leave the operator's hands-free. The operator, after starting the machine, can place the materials on the working plane so to make maximum use of the intake on the working plane for both keeping the materials standing and absorbing the nebulized adhesive. All the spray gun functions can be adjusted: quantity of adhesive, width of jet and quality of distribution even on different thicknesses. For the proper functioning of the vacuum bench it is recommended to replace the filter each time is visibly dirty or when the vacuum bench is not intaking properly. To speed up the working process it is possible to use some nets in order to reduce the idle time due to loading and unloading the pieces on the working area. A jet of air immediately before and after the adhesive nebulization keeps the nozzle constantly clean. Our systems are maintenance free. The tank is conceived in a way that allow the use of the adhesive in bag in box avoiding to make dirty the tank and to filter the glue thus preventing the contact with air which can alter its properties.

| MANUAL SPRAY SYSTEMS I598 BENCH B1510+S9+TANK |